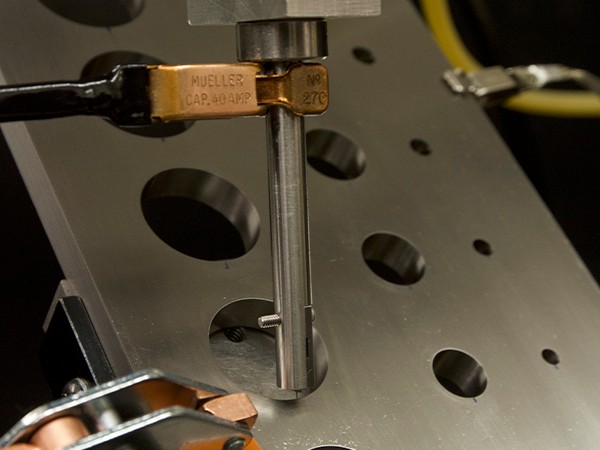

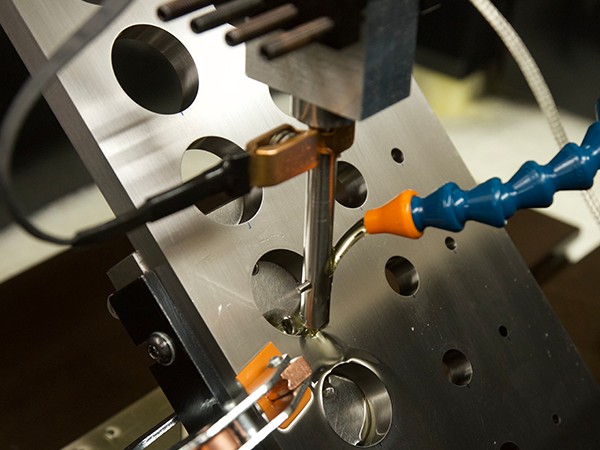

Electrical Discharge Machining (EDM)

Electrical Discharge Machining (EDM) is an integral part of UniWest’s machining capabilities. Electrically discharge machined notches, in a variety of sizes, shapes and locations, can be placed in almost all metals.

UniWest has now added two new machines, as well as doubling the size of the machine shop. The new CNC controlled machines have been modified to hold large jet engine components (up to 40” diameter), allowing UniWest to handle even the most challenging parts. The width of the notch can be tightly held and gives a fair representation of cracks typically found in the field. Calibration of eddy current measurement systems is an important factor for attaining the accuracy and precision of measurements required for quantitative nondestructive evaluation. UniWest’s unique and sophisticated EDM skills are called upon to do custom EDM work that others cannot perform. UniWest can CNC and EDM notch specific primary or master reference standards with all needed documentation; or notch customer supplied material for your specific application UniWest builds both custom and generic reference standards for all your Ultrasonic and Eddy Current testing needs.

Contact us to get started with your EDM project!

Reach Out To Us

Ready for more information or an on-site demonstration?

Click the button below to get started!