UniWest's NDT Solutions

UniWest brings critical solutions to your tough challenges through the use of non-destructive testing.

UniWest’s engineering team and application-specific approach can provide a turnkey system for applying eddy current and ultrasonic technology to your quality verification program to ensure defect-free materials and products.

Whether your special application involves manual inspection in the field, laboratory testing, or integrated in-line production system support, UniWest can provide the resources necessary to offer a complete solution to your special testing needs.

Contact us today to get started!

We can help you solve application problems in the areas of:

Surface Crack Detection:

Eddy current testing of ferrous and nonferrous metals for inspection of heavy manufacturing equipment, automotive, aerospace, and aeronautics parts, including jet engines, pipe, tube, bar, and wire. See UniWest’s EVi and EddyView II instruments.

Subsurface Crack Detection:

The UniWest multi-frequency EVi and EddyView II eddy current instruments offer multiple frequencies (from 10Hz to 15 MHz) and multiple probes to enable eddy current array testing to discover cracks before they break the surface of the metal. Applications include inspection of airframes, jet engines, and automotive parts, as well as pipe, tube, bar and wire.

Thickness Measurement:

For corrosion inspections. Useful for chemical milling applications such as airframe structures, as well as inspection of power generation equipment, wire, and tubing—wherever material loss may occur. Also useful for inspection of blade coatings, in power generation facilities, and tubing and aerospace applications. See EVi and EddyView II eddy current instruments.

Conductive Coatings Measurement:

To measure thickness of metal-clad materials in production and in field testing for wear of such parts as turbine blades, aerospace engines, automotive components, and silicon wafers and aluminum and copper processor chips. See the EddyView II and EddyView family of eddy current instruments.

Non-conductive Coatings Measurement:

For testing of material with non-conductive coatings, including in production or in field testing for wear of such parts as turbine blades, aerospace engines, computer components, silicon wafers for processor chips. See the EddyView II and EddyView family of eddy current instruments.

Condition Monitoring:

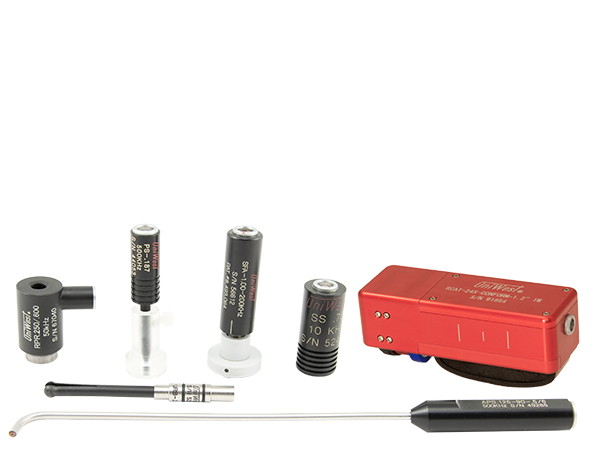

Continuous monitoring for material changes in critical parts such as jet engines, corrosion in railroad tracks and sensors. See The UniWest EddyView II instrument and the UniWest Specialty Probes.

Alloy Identification:

In-line identification of aluminum, steel and copper for material sorting, as well as tube and pipe inspection for aircraft and industry. Refer to UniWest’s EddyView II eddy current instrument.

Hardness Testing:

Hardness comparison and testing for heat-treated materials including automotive parts, See the EddyView II eddy current instrument.

Porosity Detection:

For inspection of internal discontinuities of cast materials to prevent future cracks and breaks. See UniWest’s EVi and EddyView II. Widely used in primary metals castings in the automotive industry and heavy industry (R2 wire).

In-Situ Solutions NDT:

For field inspection in difficult to reach areas of jet engines, gas turbines, sealed cavities and tank engines. See UniWest’s EVi and EddyView II.

Reach Out To Us

Ready for more information or an on-site demonstration?

Click the button below to get started!