NDT Calibration & Reference Standards

UniWest builds both custom and general purpose NDT reference calibration standards for all your nondestructive testing needs.

We can CNC and EDM notch your specific primary or master reference standard with all needed documentation; or notch your customer supplied material needed for your special application.

Contact us today to get started.

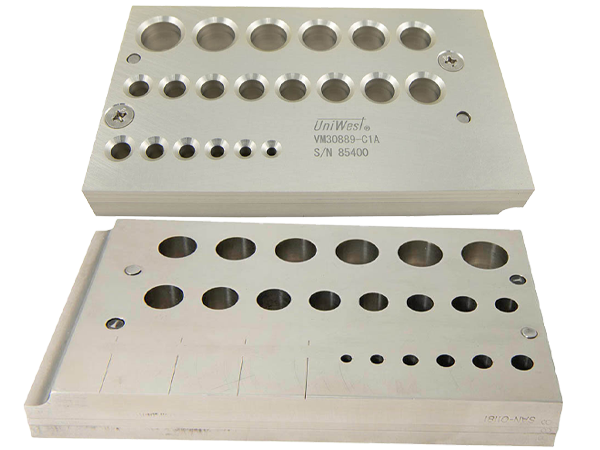

P/N: VM30889-C1A

(NSN 6635-01-092-5129)

Universal Reference Standard

This three-layer 7075-T6 aluminum eddy current calibration standard is 7” long x 4” wide x 7/8” thick. The top layer is ½” thick, the middle layer is 1/8” thick and the bottom layer is ¼” thick.

- There are 20 holes in each standard ranging from 5/32” to ¾”.

- Each hole contains one 0.030” x 0.030” EDM corner notch on the top and one on the bottom of the top layer. Each hole also contains a 0.020” deep x 0.005” ±0.002” wide EDM through notch on the bottom layer.

- There are various length and depth notches on the surface and radius of the standard.

Other materials are available as follows:

VM30889-C1T (NSN: 6635-01-390-1768): 6AL-4V Titanium

VM30889-C1S (NSN: 6635-01-512-4952): 4340/4130 Stainless Steel

VM30889-C1SS: 304 Stainless Steel

VM30889-C1I (NSN: 6635-01-512-4953): 718 Inconel

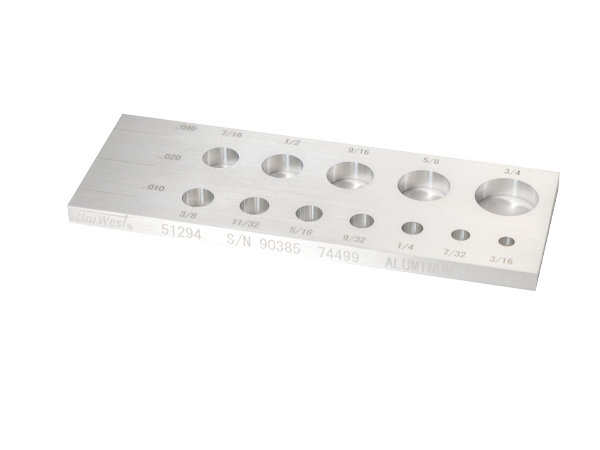

P/N: 74499

Aluminum Bolt Hole Standard

This eddy current calibration standard has 12 notched holes. Hole sizes range from 3/16 – 3/4 of an inch. For calibrating bolt hole inspections.

The standard also comes with .010, .020, and .040 thousandths EDM notches for common set up of eddy current surface inspections.

P/N: 100180

USAF Bolt Hole Eddy Current (ABHEC) Training Reference Set

This reference set is intended to represent a variety of defect types and hole conditions commonly encountered during high frequency bolt hole eddy current inspections of USAF airframe structures.

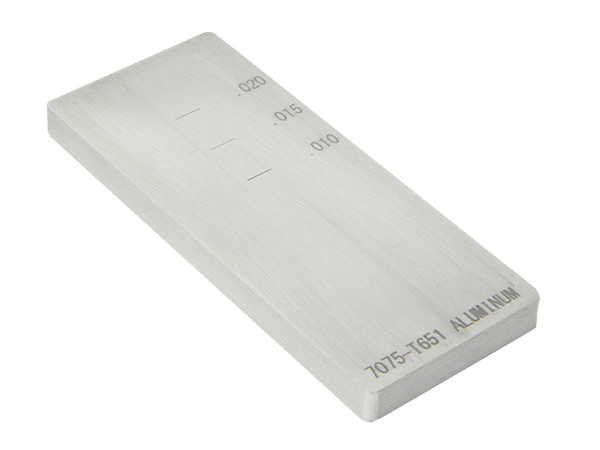

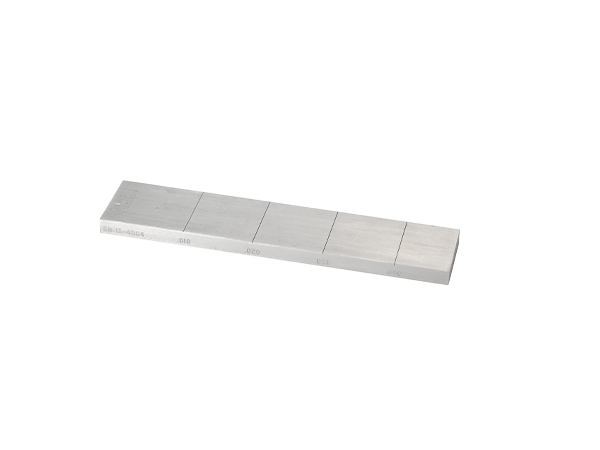

P/N: 93558A

General purpose Crack Standard

This standard comes with .010″, .020″, .030″ and .040″ EDM notches for common set up of eddy current surface inspections.

Available in; Aluminum, Magnesium, Steel, Stainless Steel, and Titanium.

P/N: 94910

Universal Eddy Current Sample and Standard Set

Available in a convenient kit form.

Test samples for conductivity are FE, TI, 304 SST, CU/NI, MAG, 7075 AL, and 1100 AL.

Surface notch standards are .008″, .020″ and .040″ deep.

Non-Conductive coating thickness samples are .003″, .006″, .009″, .012″, and .015″.

Conductive coating (CU) thickness samples are .003″, .006″, .009″, .012″ and .015″.

Gauging sample ranges from .010″ to .050″ in thickness.

A wide range of training samples are provided as well as five spaces for your own test samples. This NDT calibration standard kit is extremely useful in the lab or in the field for checking instrument performance and for training operators.

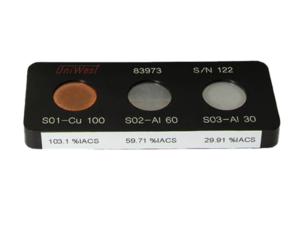

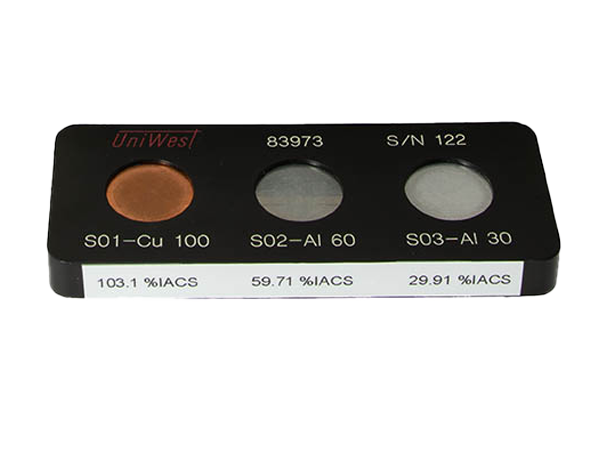

P/N: 83973

Set of 3 Conductivity Standards

Typical values:

- 29.3 %IACS

- 59.9 %IACS

- 100 %IACS

P/N: 99859

Mini Radius Standard

This aluminum standard includes a 1/8th and ¼ inch radius geometry in addition to a flat, edge and corner notch for setting up common airframe geometry’s.

This standard can also be manufactured in Titanium or Steel depending on your specific application.

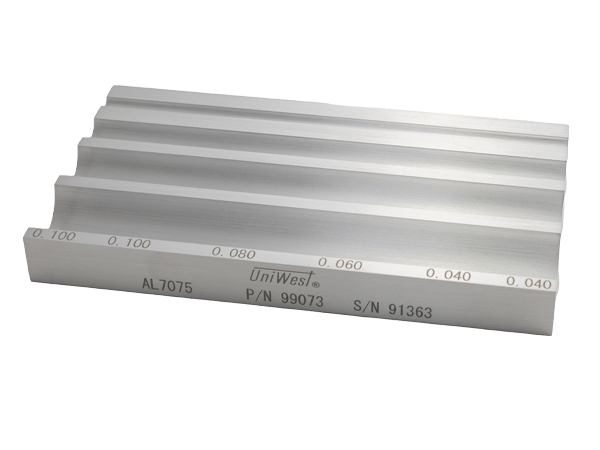

P/N: 99073

Aluminum Radius Standard

(NSN: 6635-01-609-4427)

This standard has four different radii (0.500″, 0.375″, 0.250″ and 0.125″) with surface notches of 0.100″, 0.080″, 0.060″ and 0.040″ long along the axis of the radius.

Additionally, there are corner notches and notches on the flat of the same dimensions.

General purpose standard for setting up common eddy current surface inspections.

Ultrasonic Reference Standards

UniWest can also build a variety of standard or custom ultrasonic reference standards. Contact UniWest on how we can help with your specific Ultrasonic application.

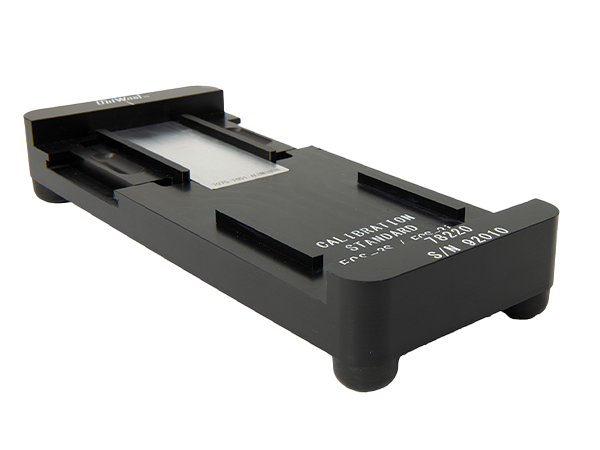

P/N: 99834

Fastener Inspection Standard

(NSN: 6635-01-609-4450)

This fastener inspection standard includes a .010″, .015″ and .020″ EDM notches to set up a range of Raised Head Fastener probes.

The adjustable V-block design allows for quick adjustment for your specific raised head faster probe.

Reach Out To Us

Ready for more information or an on-site demonstration?

Click the button below to get started!